Mechanical characteristics ※ The three-axis adopts a high-performance sliding rail design, providing high-speed and stable cutting supply. The unique design ensures that the thermal deformation of the head is the same as that of the Y-axis and can be automatically compensated The spindle head is a heavy box structure with reinforced internal ribs and high rigidity. Using C3 grade precision roller screw combined with precision nut and tail end pre tensioning device, ensuring that the thermal deformation of the body's back gap reaches the minimum value The G-type machine adopts a heavy cutting gear type spindle head, which is a full tooth high and low two-stage variable speed transmission. The imported gears used are all made of chromium steel alloy material. Made by infiltration solution hardening treatment and JIB-0 precision grinding, to ensure the long service life and machining accuracy of the gearbox bearing gears, the spindle head adopts dual cooling inside and outside.

15989519333 (Mr Xu)

Online consultation Message consultation

Main specifications and technical parameters

| Main technical parameters |

||||

| Mechanical specifications |

name |

Specifications |

Company |

|

| trip |

X-axis travel |

800 |

mm |

|

| Travel Y-axis |

500 |

mm |

||

| Z-axis travel |

550 |

mm |

||

| Distance from spindle nose to worktable |

110-610 |

mm |

||

| Distance from spindle center to column slide surface |

565 |

mm |

||

| workbench |

Workbench size |

1050×500 |

mm |

|

| maximum load |

600 |

kg |

||

| T-shaped groove (number of grooves - size - spacing) |

5-18-90 |

mm |

||

| principal axis |

Spindle speed |

8000 |

rpm |

|

| Main spindle tool holder form |

BT-40 |

|||

| Spindle diameter |

Ø150 |

mm |

||

| Transmission mode |

Belt type |

|||

| Feed rate |

Fast moving speed X/Y/Z |

12 / 12/ 12 |

m/min |

|

| feed rate |

1~8000 |

mm/min |

||

| Machine accuracy |

X/Y/Z-axis positioning accuracy |

±0.005/300 |

mm |

|

| X/Y/Z axis repetition accuracy |

±0.003 |

mm |

||

| motor |

Spindle motor |

7.5 |

KW |

|

| X. Y and Z-axis drive motors |

3.0/3.0/3.0 |

KW |

||

| Oil pump |

750 |

W |

||

| Tool magazine (optional) |

Tool magazine capacity |

24 |

branch |

|

| Automatic tool change type |

Circular blade arm type |

|||

| Knife handle specifications |

BT-40 |

|||

| Knife handle pull nail |

45 |

degree |

||

| Maximum tool length |

300 |

mm |

||

| Maximum tool diameter |

Full of knives |

Ø80 |

mm |

|

| Neighboring empty knife |

Ø125 |

mm |

||

| Maximum tool weight |

8 |

kg |

||

| Tool change time |

1.8 |

sec |

||

| Land occupation space |

Mechanical height |

2300 |

mm |

|

| Floor space (length x width) |

2750*2500 |

mm |

||

| Mechanical weight |

5500 |

kg |

||

| Total electrical capacity |

20 |

KVA |

||

| Pressure demand |

0.5 ~ 0.8 |

MPa |

||

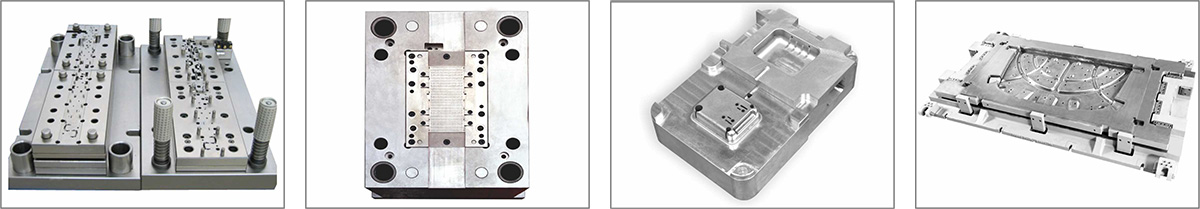

Processing applicationsProcessing application

Precision molds, parts, hardware, automotive, aviation